Water Treatment Products

Residential & Commercial

| R.O. System and Replacement Filters | Water Softeners | Whole house Filtration |

| Pond Equipment | U.V. Lamps | Water Flow Meters |

| Pool Equiment | Waste Water Treatment | Custom Projects |

Industrial

| Custom Made Systems (R.O., Micro, Ultra and Nano Filtration) | Reverse Osmosis Membranes |

| Filters (Zeolite, Carbon, Sand) | Flow Meters and Computers |

| Automatic Self Cleaning Filters | Waste Water Treatment |

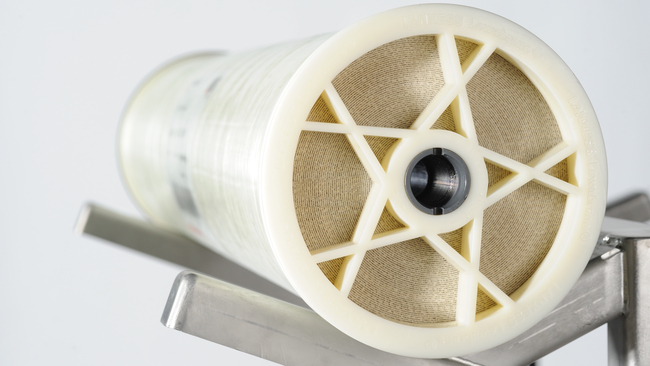

LEWABRANE® RO B090 HF 4040

| Product Group: | High flow |

| Permeate flow rate | 9.4 m³/day (2,500 gpd) |

| Salt rejection | 99.5% |

| Applications: |

|

| Material number | 56923339 |

| HTS number | 84209990 |

| Packaging Format: |

We are offering Lewabrane membrane separation elements for reverse osmosis. The main field of application for the currently available RO membrane separation elements is desalination of brackish water needed in many industrial applications, including the production of boiler feed water required in power stations. RO membrane and ion exchange water treatment processes complement each other perfectly, and the high treated water quality helps to prolong the service life of, for example, turbines and steam generators via protection against fouling, scale formation and corrosion.

Another application for the new Lewabrane RO membrane elements is the preparation of feedwater that customers can use for electrodeionization (EDI) applications. The EDI process allows for the production of ultrapure water with very low electrical conductivity without the need for regeneration chemicals. High performance RO membranes can provide a reduced load on the downstream EDI process improving cost performance. These membrane based processes have been increasingly adopted by the water treatment industry for preparation of high purity water.

As premium products, membrane elements in the Lewabrane RO product family meet top quality standards and comply with all requirements for industrial use. With a standard length of 40 inches (1,016 mm) and a diameter of eight inches, Lewabrane RO B400 HR has an active membrane surface area of 400 square feet (37.2 m²). Salt rejection is 99.7 % for a daily permeate flow rate of 37.9 m³ (average value under standard industry reference conditions; salt concentration in the feed: 2000 ppm, 225 psi, pH 7, 25 °C, and a single element recovery of 15 %).

The Lewabrane RO B090 HF 4040 element has the same length but a diameter of only four inches and an active membrane surface area of 90 square feet (8.7 m²). “Thanks to a new ATD (anti-telescoping device) design, the surface area of the membranes exceeds that of other commercially available elements by almost 6 percent,” explains Sharpe. The new LANXESS filtration element owes its superior average permeate flow rate of 2500 gallons per day (9.4 m³ per day) under standard conditions at a rejection level of 99.5 % to the greater active surface area of the RO membrane available inside the RO element.

All of our products are state of the art technology.